The Custom Constraints table allows you to configure the maximum number of product flows for a certain supply chain object (or a group of objects).

- When the limit is set on a group, the CPLEX solver applies this limit to each object of the group and not to the group itself. Another example of this behavior would be enabling an expand toggle button of a policy defined for a group of objects in the Product Flows table.

- The flows are chosen anew for every period defined in the Periods table.

You may limit the number of incoming or outgoing flows. The type of object for which you limit flows depends on the type of flow that you intend to limit:

- Limit inputs — limits the number of incoming flows for: customers, distribution centers, factories.

- Limit outputs — limits the number of outgoing flows for: distribution centers, factories, suppliers.

To limit the number of product flows for a customer

-

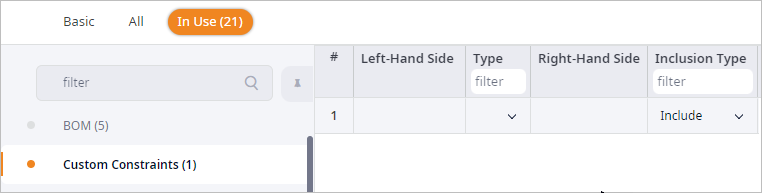

Open the Custom Constraints table and click Add to create a

new record.

-

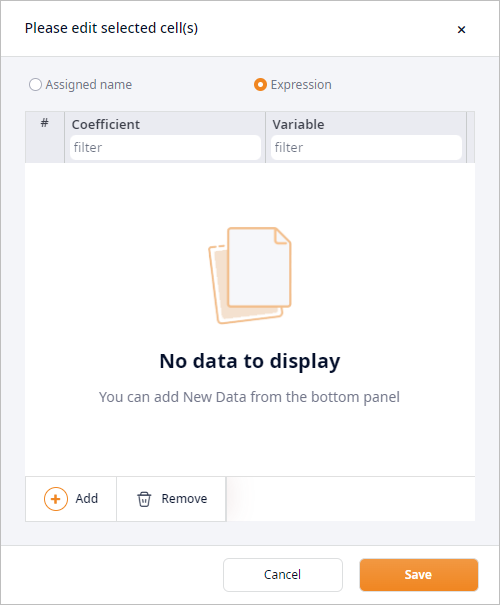

Double-click the cell in the Left-Hand Side column to open the dialog box.

-

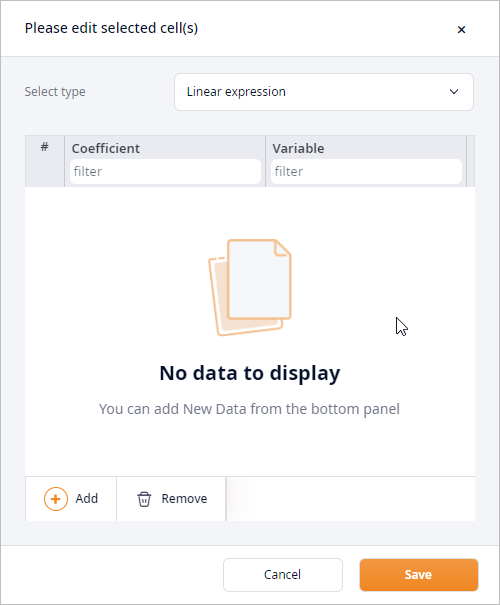

Click Add to create a new expression.

The new expression will be created with the default Coefficient 1, which defines the maximum number of product flows for the object that we will further define in the Right-Hand Side.

-

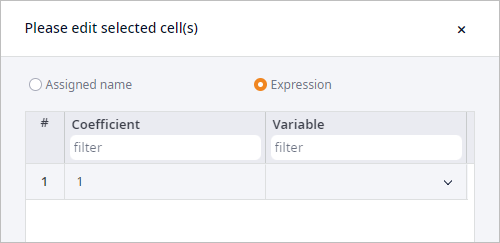

Set the Coefficient to 5 and click

Save to close the dialog box.

In this way we define that the object that we will further specify will have 5 product sources.Please note that there is a possibility of zero product flows.

-

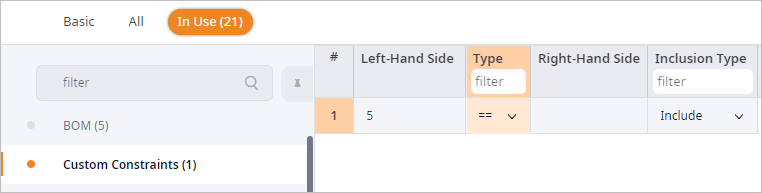

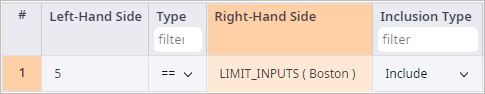

Set the Type value to ==, since we want to have the exact number of flows.

-

Now double-click the cell in the Right-Hand Side column to define the object and its flows that we want to limit.

-

Click the Select type drop-down list and select Limit inputs.

In this way we tell anyLogistix to limit the incoming product flows for the object that we will define with the next step.

The options in the dialog box will now correspond to the selected type of variable.

- Now click the Limited site drop-down list and select the required customer.

-

Click Save to close the dialog box.

The record limiting the maximum number of incoming flows for the Boston customer now looks like this:

- That's it. You may now run the experiment and analyze the results.

anyLogistix considers all the possible product flows when limiting their number for the defined object(s).

Several flows that are set up between two objects to deliver different products are considered to be a single flow between these objects.

A properly defined product flow consists of:

- Path defined in the Paths table.

- Flow defined in the Product Flows table.

In the following cases a product flow will not be considered by anyLogistix:

- Objects are connected by a properly defined path but there is no product flow defined between these objects.

- The product flow is defined between the objects, but there is no path connecting them.

If the desired number of flows exceeds the available number of flows for the current object(s), anyLogistix will create the lacking number of flows using the idle existing objects. Such objects are considered irrelevant regarding the objects defined in the Right-Hand side, but they will be used exclusively to meet the requested number of flows.

e.g. A customer is supplied by 3 distribution centers. You specify the number of input flows for this customer to be 4. In this case anyLogistix will create the missing flow by using a distribution center that is not supplying this customer, but is connected to it by a path. This is a zero product flow. It will not affect the calculations made by NO in any way since no products will be delivered through it.

-

How can we improve this article?

-