This example shows how to configure a scenario to achieve the most profitable supply chain configuration. The profit is maximized by selecting the best configuration of distribution centers considering expenses defined in the Facility Expenses table and the transportation costs (defined in the Paths table) for delivering products to the customers.

We consider a global supply chain comprising:

- Smartphone factory in China

- Components suppliers in China

- The large number of potential distribution centers that fulfill the demand of customers in North America (the USA and Canada), Europe, and Australia.

- Each customer orders 2 smartphones every day

- All sites are initially closed

- Initial costs constitute $100 000.

- The cost of producing one smartphone constitutes $10

- Other costs constitute $50 per day.

| Country/Product | Smartphone |

|---|---|

| Europe | 3% |

| USA | 7% |

| Australia | 8% |

| Canada | 4% |

We decided to have one distribution center per continent, so we will get 3 locations for distribution centers from the list of the potential distribution centers in the results of the optimization.

Find the best configuration of distribution centers considering transportation, initial costs, and the list of locations where we could build warehouses.

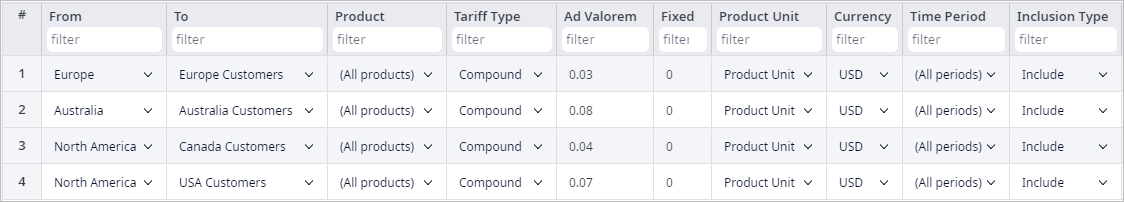

Since there are customers located in different countries and even continents, tariffs should be considered. As we can see in the table above every region has its tariffs for the product we want to deliver. We need to specify tariffs for every customer in the Tariffs table. Because of the big number of similar objects, we can use predefined groups to decrease the number of rows and simplify understanding of the table.

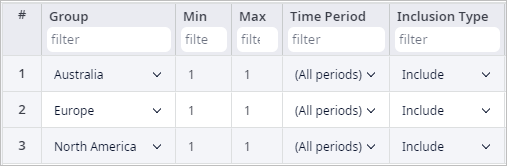

Also there are special requirements for the number of sites in the defined regions considering the previously defined Restrictions. These constraints are configured in the Assets Constraints table.

The result of the experiment offers to open distribution centers in:

- Sydney (Australia)

- Berlin (Germany)

- Chicago (USA)

The Iterations panel shows the result of the experiment with all the possible combinations sorted per Profit KPI metric.

The top iteration card is the best one.

The data on other details is shown in the corresponding tables:

-

How can we improve this article?

-