Prior to running the experiment you must make sure that your scenario is properly configured:

- Fleet — the required sites must have fleets.

- Vehicle types — vehicles can be used only on the paths that you define them for.

-

Paths — if a customer is specified in the sourcing policy but has no paths leading to and from it, it will not be serviced, i.e., to properly generate a milk run, the

Paths table must contain records allowing a vehicle to set off from a site, reach the first customer, continue to move from one customer

to another one, and finally, complete the milk run by returning back to the site it set off (if the Return vehicles back to site

setting is selected in the experiment settings).

Make sure that the Paths table contains the following type of records:

- Site to Customer

- Customer to Customer

- Customer to Site

To run the Last mile optimization experiment

-

Click the required scenario of the

type in the anyLogistix

scenarios ribbon.

type in the anyLogistix

scenarios ribbon.

-

Navigate to the experiments section and select Last mile optimization.

Experiment settings will open over the map area. - Define the scope of data the experiment should process by adjusting the settings of the MANAGE ORDERS section.

- Click the Preview orders toggle button to open the Preview Orders dialog box with the table of orders that fit the defined settings of the MANAGE ORDERS section.

- If required, adjust the parameters of the EXPERIMENT SETTINGS section.

- In case you feel that a more optimized cost of delivering products may possibly be achieved, you may try changing the Solution strategy advanced setting.

-

Click

Run to start the experiment execution.

Run to start the experiment execution.

The log view will appear with a progress bar showing the progress of downloading the required routes. The experiment will be executed once all the routes have been downloaded. The log view will now show the progress of the experiment.

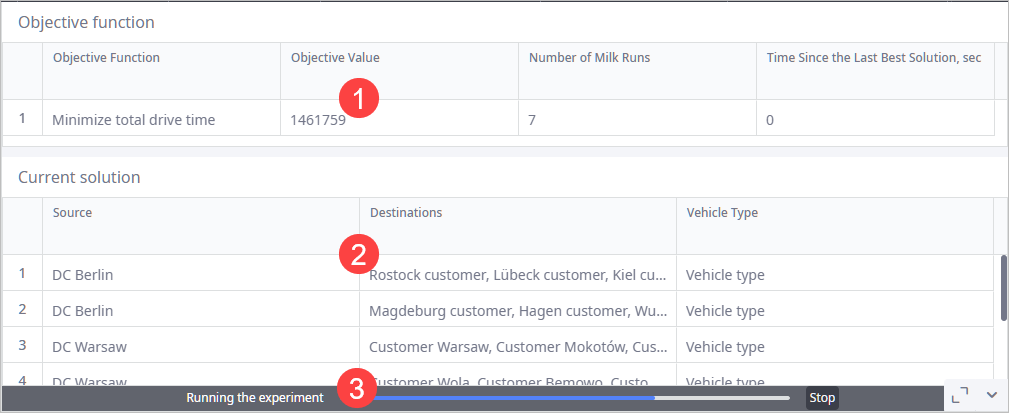

The optimizer log view is available only during the experiment run. It shows the current progress of the experiment:

-

Objective function — the best current solution.

If a better solution is found, it will substitute the current table record.

The table comprises:

- Objective Function — the name of the objective function of the experiment (Minimize total travel time). The objective function will change to Minimize Total Travel Time + Shipment Duration if the Minimize shipment duration parameter is selected in the experiment settings.

- Objective Value — the value of the objective function in the best found solution.

- Number of Milk Runs — the number of milk runs the best solution contains.

- Time Since the Last Best Solution, sec — shows tha elapsed time from the moment the current best solution has been found. This information can be used to adjust the Optimization time limit parameter. For example, if the best solution was found within five minutes from the experiment start, then you may try reducing the Optimization time limit to that period of time.

-

Current solution — all the milk runs that were generated within the current best solution.

The table comprises:

- Source — the distribution center or factory, from which a vehicle set off to visit customers.

- Destinations — the list of all customers the vehicle visited within this milk run.

- Vehicle Type — the vehicle type that was used within this milk run.

- Running the experiment — the progress bar showing the current progress of the experiment.

If you encounter the "Infeasible solution" pop-up message, make sure your scenario does not contain errors. If the scenario data is correct:

- Check if all the required orders are selected in the Preview Orders table.

- Increase the Optimization time limit value.

- Check that Maximum shipment duration and Maximum vehicle idle time settings do not contradict each other. Increasing their values might also be an option.

- Make sure that the Maximum shipment duration considers the Return vehicles back site setting (if the latter is selected).

- Check that the fleet has enough vehicles to deliver all the orders. Also, the fleet must not have too many vehicles, since it will significantly increase the problem the optimizer is solving.

- The experiment duration period may be too long.

To have a better understanding of the possible cause you may:

- Select the Relax time windows and / or Relax gates settings.

- Gradually increase the Dropped orders rate setting to allow more orders to be dropped.

Finally, you may try changing the Solution strategy

in the experiment's ADVANCED SETTINGS.

Please note that changing the advanced settings is not recommended.

It is better to contact support if the above listed measures were insufficient.

-

How can we improve this article?

-