This example illustrates to capture the production process with a high level of detail with the aid of AnyLogic Fluid library. We will also learn how to define production in batches.

The advantage of anyLogistix is the possibility to extend any object using AnyLogic. This allows you to model site operations inside four walls.

This example illustrates how you can capture production process in a high level of detail with the aid of AnyLogic Fluid library.

We consider a supply chain in Switzerland comprising:

- Yogurt Factory in Sarnen which is supplied with milk and fruits

- Fruits and Milk suppliers

- Two distribution centers located in Zurich and Lausanne respectively

- Customers located in the 50 largest cities of Switzerland

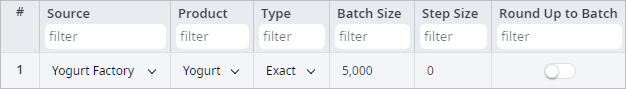

Products like yogurt are produced in batches, that is why we are using the Production Batch table. We set the minimum amount of yogurt the factory can produce when receiving an order (Batch Size) to 5000 pcs. Also, we did not define the Step Size, so the amount of yogurt the factory can produce is always a multiple of the batch size.

The advantage of anyLogistix is the ability to extend any object using AnyLogic simulation software. This allows us to model site operations inside four walls.

- Once a week yogurt bottles are delivered to customers in Switzerland

- We assume that on average people consume 50 yogurt bottles per year

- The supply chain covers 10% of the total demand of the cities

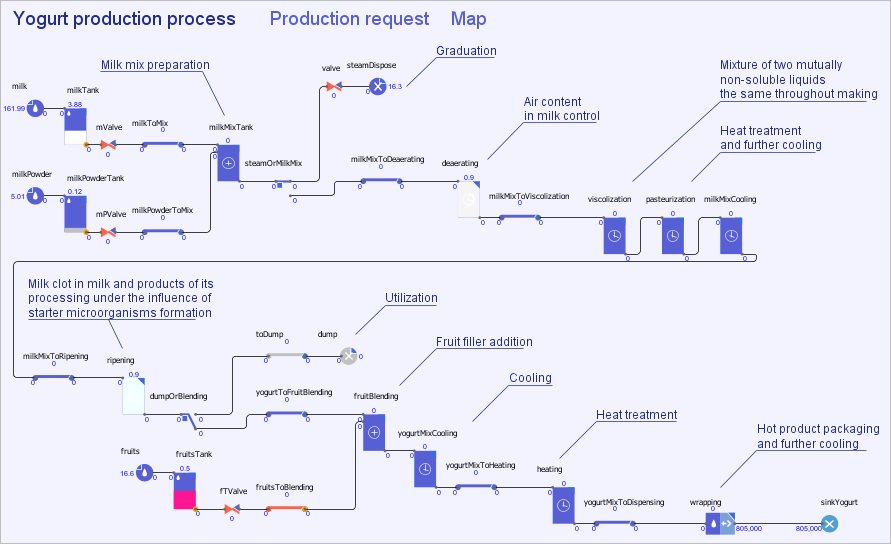

The yogurt production comprises the following stages:

- Solid content normalization: milk mix preparation (97% milk and 3% milk powder) and graduation (10% volume).

- Deaerating milk.

- Viscolization — blending of two mutually non-soluble liquids, making them the same throughout.

- Pasteurization — heat treatment.

- Cooling.

- Ripening — milk clotting in milk and products of its processing under the influence of starter microorganisms’ formation.

- Adding Fruit filler. If there is not enough fruits on factory the process will switch to product utilization.

- Cooling.

- Heat treatment.

- Hot product packaging and further cooling.

It takes 7.5 hours to produce 1 batch of yogurt.

In this example the production process is configured based on the real-life factory, so all the production timings are defined in the extension model and cannot be changed from anyLogistix. We can only change the size of the production batch.

The production flowchart can be seen below.

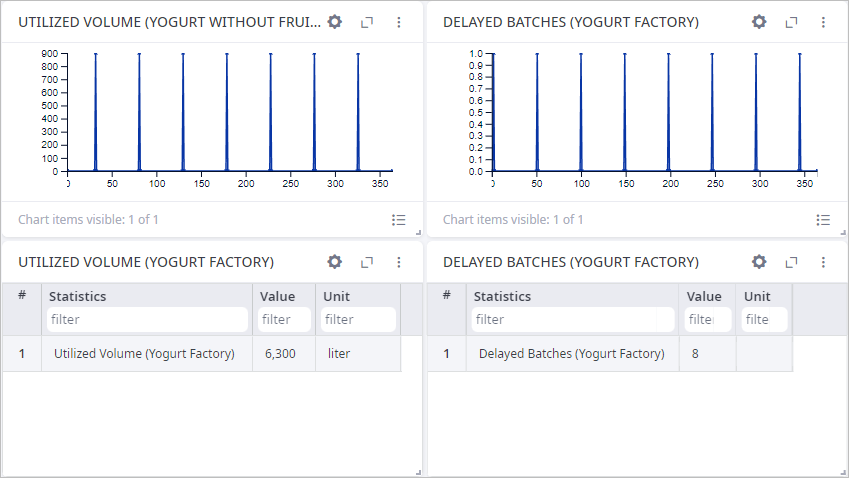

Analyze production process efficiency:

- Estimate the volume of utilized milk mixture

- Define how often the production was delayed

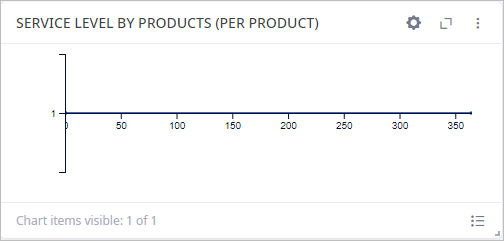

- Estimate the service level

The Yogurt Factory extension also provides custom statistics:

- Utilized volume — shows the statistics on the amount of product that was wasted due to fruit filler shortage.

- Delayed Batches — shows the statistics on the number of batches that were delayed due to product shortage.

In the Production Failures tab we can see the statistics on: the days of simulation, the time when production issue occurred, the exact amount of wasted products, and the delayed batches.

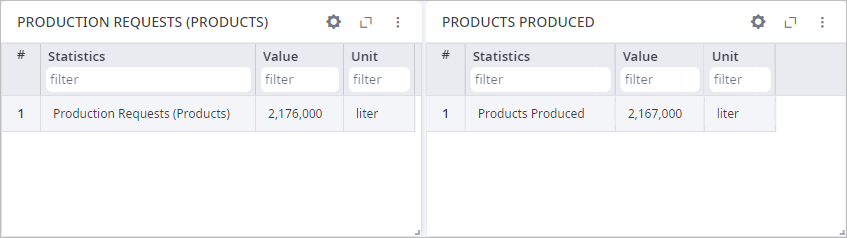

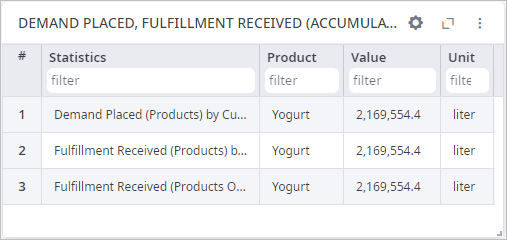

The received data allows us to estimate the amount of used milk by:

- Calculating the proportion of milk mixture in one yogurt

- Calculating the number of produced yogurts

- Multiplying the values obtained

The result shows that the inventory policies for raw materials replenishment satisfy production needs. However, for continuous production we must consider the time it takes to deliver the raw materials to the factory, that is why the produced volume does not match the production request.

But since the customer demand was lower than the production request, the service level was 100%.

anyLogistix extensions are built using AnyLogic simulation software and help to simulate your unique processes, which cannot be defined by the default options to create a powerful and flexible simulation model.

-

How can we improve this article?

-