In this scenario, we will see the way of using a special type of distribution center object, which has a modified structure and is made via AnyLogic simulation software. Also, in this scenario, we will learn how to specify sale batches and special rules for adjusting ordering product amounts.

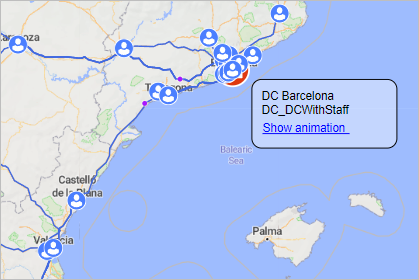

We consider a scenario with a supply chain in Spain comprising:

- 3 suppliers, which deliver fruits (apples, oranges and bananas)

- Customers in the 100 largest cities of the country

- 5 distribution centers located in Utrera, Barcelona, Gijon, Elche and Madrid

To estimate the demand, we will assume that:

- On average people consume 75 kg of fruits a year

- Supply chain covers 1% of the total demand of the cities

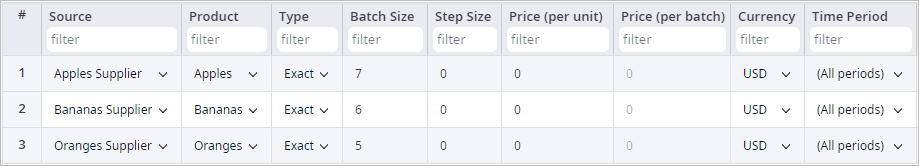

Suppliers can only sell products in batches, so we need to specify the size of the batch. In the Sale Batch table, we specified suppliers as the source of products, the demanded product, the type of the batches (Exact means that we can only order the amount defined in the Batch Size), and the Batch Size.

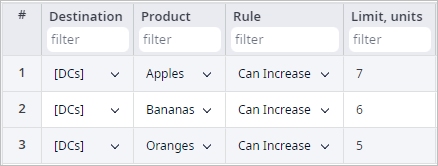

Since suppliers sell products only in batches, we need to order batches of products. But the amount of product to order does not always equal the batches size, so we need to consider rules to adjust the ordering amount to the batch size. The Ordering Rules table is usually used with the Sale Batch table. In this table we defined that the amount of product, that distribution center needs to order, can be increased up to the batch size value.

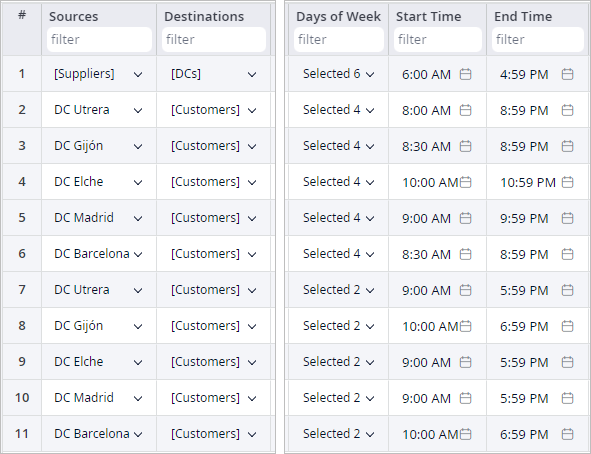

Also, the facilities in this supply chain are working according to the special schedule. That means that only during the defined periods a facility can ship products to the destination. If the order is received beyond the specified period, it will be postponed until the next working period. This schedule is defined in the Shipping table.

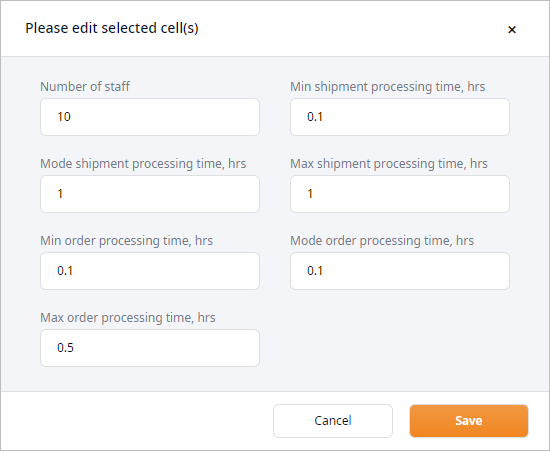

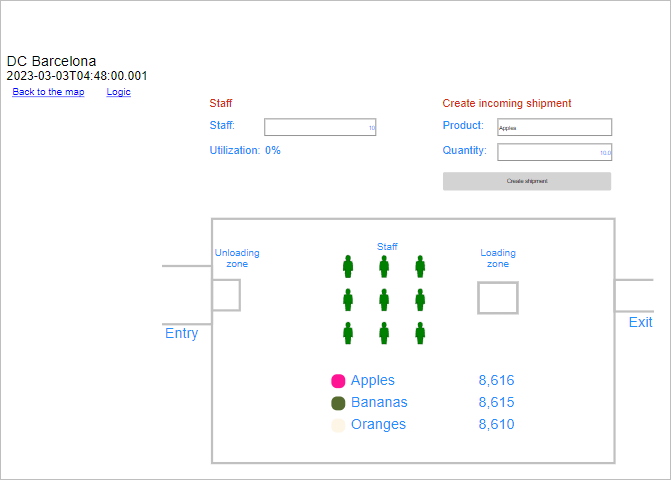

The advantage of anyLogistix is the ability to extend any object using AnyLogic simulation software. In this example, we used an extension called DC with Staff. It is a basic distribution center object with additional features. It helps us to analyze the performance of the facility based on the staff utilized. We can define default settings for each distribution center by opening the Additional Parameters cell from the Distribution Centers table. Using these settings, we can describe the required facility in more detail.

Fruit processing at the site is organized in the following way: fruits are delivered to the warehouse by trucks, the site staff then unloads products and moves them to the storage zone. For each order the warehouse receives, the staff prepares the required number of products and loads it to the lorry.

Since we redefined the loading and unloading processes in this extension, the loading and unloading gates defined in the corresponding input table for these objects will not be considered.

This scheme represents the DC with Staff facility. We can open this scheme during the simulation runtime for any facility of this type by clicking the object we want to observe, and clicking the Show animation link.

This extension allows us to:

- Check the actual number of products in storage

- Change the number of workers in this facility during the simulation run (by entering the number into the Staff field),

- Create a new incoming shipment from the supplier, and analyze the new value of staff utilization

All changes will affect this facility only.

During the simulation run, we can change the number of workers in the Staff field, it will affect the two main actions of this warehouse: unloading incoming vehicles and loading outgoing ones. Since the number of products stays the same, but the number of workers changes, the time spent on performing these actions will change as well.

Also, we can create an incoming shipment which will simply create an order for a specified quantity of a certain product for the supplier. It takes some time needed to deliver the order from the supplier, and then it will appear at the entrance of the warehouse. It can be useful to check the performance of the defined number of staff in case of instability of supply.

Estimate staff utilization and how it affects ELT service level.

Let us run the Simulation experiment and analyze the results.

The data in the ELT Service Level tab shows that the performance of the supply chain is not perfect. The issue with the Service Level is caused by the schedule of the distribution centers. The orders that the distribution center receives on Sunday are postponed till Monday.

This extension provides three additional statistics, which we added to the dashboard of the Simulation experiment in the Staff Utilization tab:

- Staff Busy Time — statistics on the amount of time the available staff is busy processing tasks.

- Staff Idle Time — statistics on the amount of time the available staff is idle with no work to do.

- Staff Utilization — statistics on the ratio of the staff occupied time to all time.

These statistics will help us to analyze the actual warehouse workers’ daily workload.

anyLogistix extensions are built using AnyLogic and help to simulate your unique processes, and create a powerful and flexible simulation model.

-

How can we improve this article?

-