If the Experiment settings panel is not open, click

in the experiments controls.

in the experiments controls.

-

Experiment duration — the period of time that will be processed by the experiment.

-

All periods — [this option is set by default] Experiment will consider all periods specified in the

Periods table.

The actual experiment duration is defined as the starting date of the first period and the ending date of the last period.

-

Selected periods — experiment will consider only the periods that you specify in the

Start period and End period fields:

- Start period — [visible if Selected periods option is selected] specify the period, the starting date of which will be used as the starting date of the experiment.

- End period — [visible if Selected periods option is selected] specify the period, the ending date of which will be used as the ending date of the experiment.

The experiment duration will constitute the whole period between the starting date of the period specified in the Start period field and the ending date of the period specified in the End period field.

-

All periods — [this option is set by default] Experiment will consider all periods specified in the

Periods table.

-

Analyzed by

- Number of sites — specify the number of sites that you would like to use in your supply chain. The GFA experiment will find the optimal locations for the specified number of sites.

-

Service distance — specify the maximum distance between a customer (or a site) and a distribution center.

The GFA experiment will calculate the optimal number of sites considering the specified distance to a customer.

Distribution center location is affected by the Suppliers to sites transportation discount, % parameter.

-

Suppliers to sites transportation discount, %

— allows you to vary transportation cost from a supplier to distribution centers (both existing and the ones the experiment will generate).

The larger the discount, the less influence a supplier has on a site location, and vice versa. - Distance step for statistics — the distance step, that will be used to visualize the data of the Total Demand Coverage by Distance statistic.

- Product stats unit — the measurement unit of products within this experiment.

- Distance stats unit — the measurement unit of distance within this experiment.

- New site icon — opens the Define The New Icon dialog box, which allows you to create new icon, and set it to all distribution centers created by the GFA experiment.

-

Advanced settings — [available if the Show advanced experiment settings

checkbox is selected in the anyLogistix settings]

a set of additional parameters that affect calculation logic.

- Parameters

-

Use the parameters carefully to fine-tune the experiment. Note that changes you make may significantly increase calculation time.

-

— click to reset the advanced experiment settings.

— click to reset the advanced experiment settings.

- Max iterations — number of iterations with a random set of initial cluster points.

-

Max heat length — limits heat map for demand. It is calculated as:

max(2, min(maxHeatLength, nLocations / divider)).

- Divider — changes heat map granularity.

-

The table allows you to specify the groups of customers / sites or both types of objects to be considered during the GFA experiment. For more details refer here. The table contains the following columns:

- Enlarge — expands the table window. To close the expanded window, click

.

. - # — shows the ordinal numbers, denoting the order of the table records.

- Destination — contains groups (either default or user-defined) of the available customers / sites involved in the scenario's supply chain.

- Included — shows the current status of the group, i.e., whether it is considered or not during the GFA experiment.

Types of objects to consider

- Customers — the experiment will find the optimal locations for sites supplying the selected customers.

- Sites — the experiment will find the optimal locations for super sites, supplying the selected sites.

- Combination of customers and sites — the experiment will find the optimal locations for super sites that will be supplying the selected objects.

You might need to redesign the existing sourcing policies (defined in the Sourcing table) to avoid crosslinking of locations from the selected groups of objects. For details refer here.

Defining a super site location for a distribution center and several customers

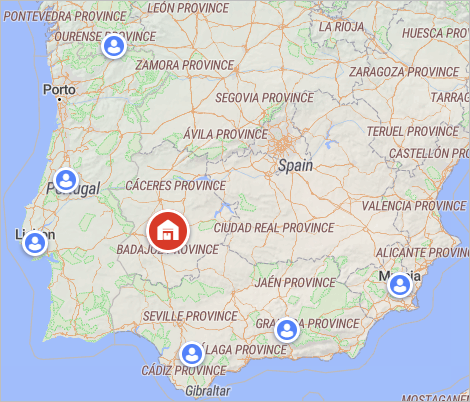

For example, we have a supply chain in Spain with one distribution center and six customers (see screenshot below). The distribution center is supplying three customers in the western part of Spain (next to Ourense, in Portugal, and in Lisbon). You want to find the optimal location for a sourcing site that will be supplying the existing distribution center and the three clients in the northern part of Spain.

- Navigate to the Sourcing table and make sure that the customers from the northern part are not connected to the existing distribution center.

- Navigate to the Groups

table and create either of the following (the created groups will be available in the table of

Destinations):

- Group containing all the required objects (the existing distribution center and the three northern customers). This will add one record to the Destination column in the table of Destinations.

- Two groups, one with the existing distribution center, and the other one with the three northern customers. This will add two records to the Destination column in the table of Destinations.

- Navigate to the experiment settings and select the required group(s) of objects. The experiment will find the optimized location for the super site considering the existing distribution center and the specified customers.

-

How can we improve this article?

-