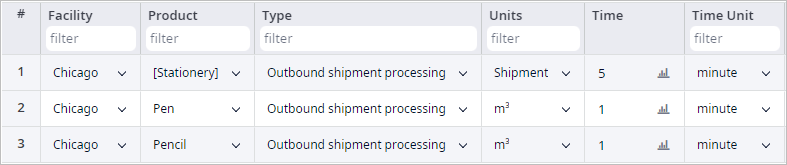

This table is considered only by the SIM-based experiments.

Orders and shipments within the supply chain are processed with certain time delays.

In the Processing Time table, you define policies for calculating processing time for orders and shipments. Processing time policy is set on the facility level and is applied based on the product, performed operation (order or shipment) and operation's direction (inbound or outbound).

| Column | Description |

|---|---|

|

Facility |

Defines the facility, for which the processing time policy is set. A source may be a single object as well as a group of objects defined by the user. The cell contains a list of facilities (previously defined in the Customers, Distribution Centers, Factories and Suppliers tables). The list also includes groups from the Groups table, if any. |

|

Product |

Defines the product for which processing time policy is set. If a product is selected, processing time policy applies only to orders / shipments containing this product. If a group of products is selected, then processing time is multiplied by the number of products in this group. If this is not the desired case, then click the Split rows button. The cell contains a list of products (defined in the Products table). |

|

Type |

Defines the type of the processing time calculation policy, which is a combination of the performed operation's type (order or shipment) and operation's direction (inbound or outbound):

|

|

Units |

Defines the unit that the specified Processing Time will be spent on: The list of available units comprises the units defined in both the Manage units dialog and the Units table.

Learn how the processing time is calculated if Shipment or Vehicle is set as the processed unit: |

|

Time |

Defines the processing time in the specified Time Unit for the specified unit in the Units column. The processing time value can be either fixed or stochastic (defined by a probability distribution). For details on providing fixed or stochastic values refer to this section. |

|

Time Unit |

Specify the time unit that the Processing Time is expressed in. The list of available units comprises the units defined in the Manage units dialog. |

Processing time is calculated in the following way (unless Shipment or Vehicle is set as the processed unit):

- Order / shipment amount is represented in Units, which can be orders, shipments, product units, volume or weight units.

- The resulting number of Units, is multiplied by the processing Time.

You can define multiple processing time policies for a facility / product combination: for example, an order-based policy and a weight-based policy. The resulting processing time value for a single operation will be the sum of the defined processing time values.

Similar concepts apply to calculating processing cost. Refer to the Processing Cost table for details.

Processing time will be calculated in a different way if Shipment or Vehicle is defined as a unit for processing (All products) or a user-defined group of products (defined in the Product Groups table). The calculation will depend on the records the table contains:

-

If the table contains records with processing times defined for separate product(s) of the group

(not necessarily all of them), the processing time will constitute the sum of processing times of all such records.

On the screenshot below the processing time of the Stationery

group of products constitutes 7 minutes, where:

- 5 minutes is required to process the group.

- 2 minutes is required to additionally process two products (1 minute per each) that are a part of the Stationery group.

- If the table does not contain separate records with products from the group, the processing time will be calculated in a regular way, i.e., Units * Time.

-

How can we improve this article?

-