In the previous phase we defined the production policy and launched the experiment. In this phase we will:

- Add raw materials

- Add suppliers

- Update the sourcing policies

- Update the inventory policies

Let us start with adding the raw materials.

Add raw materials

- Switch to the scenario input data by clicking the supply chain mode tile.

- Open the Products table and click Add to add a new product.

- Click the Name column cell and rename the product to Plastic.

- Set its Selling Price to 0.

- Set its Cost to 1,316. This is what we will pay for 1 cubic meter of plastic.

- Set its Currency to GBP. There is no need to adjust the settings of the project, the required measurement units are imported with the scenario, so you can simply double-click the cell and select the required value.

- In the same way add one more raw product and:

- Name it Silicon.

- Set its Selling Price to 0.

- Set its Cost to 20.

- Set its Currency to GBP.

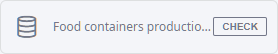

Eventually the table must contain the following data:

We have defined the raw materials required to manufacture our products.

Now we will define the unit conversion rules for the raw materials. These rules are required, since the experiment collects statistics in pcs (pieces), while the measurement units of the raw materials is cubic meter.

Define conversion rules

- Click the search box above the list of tables, type Unit Conversions, then select the table from the filtered list.

- Click Add to create a new record.

- Double-click the Product cell and select Plastic.

- Now define that 1 m3 of plastic is equal to 1 pcs.

- In the same way create a new record for the Silicon product.

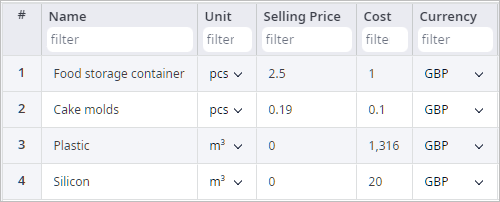

Eventually the table must have the following data:

We have defined the conversion rules for the measurement units of the raw materials.

Let us create a group of products that we produce. This step will simplify the process of defining policies as we will define them for the whole group, rather than for each product.

Create a group of products

- In the search field type product groups, then select the table from the filtered list.

- Click Add to create a new record.

- Click the Name column cell and rename the group to Products.

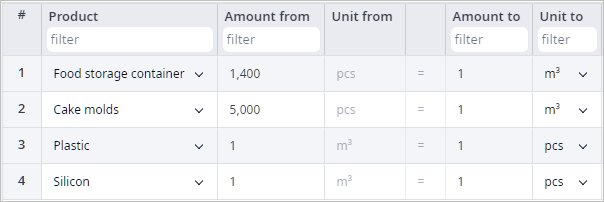

- Double-click the cell in the Products column cell to open a dialog box.

- Enable the toggle buttons of the Food storage container and Cake molds products.

- Click Save to close the dialog box.

Now we will add suppliers to the supply chain.

Add suppliers

- In the search field type Suppliers, then select the table from the filtered list.

- Create two records by clicking Add.

- Rename the new objects to Plastic supplier and Silicon supplier respectively.

Now we will define locations of the suppliers

Define locations

- Navigate to the Locations table by typing Locations in the search field.

- Scroll down to the end of the table.

- In the City column cell of the Plastic supplier type Cardiff.

- In the City column cell of the Silicon supplier type Gillingham.

- In the Country column cells of both suppliers type United Kingdom.

- Finally, click the Autofill Coordinates buttons in the Autofill Coordinates column cells for both suppliers.

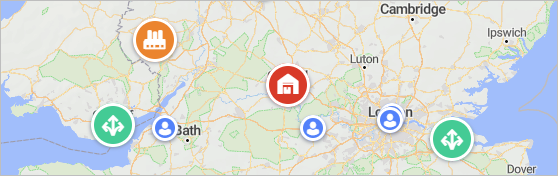

The objects will be moved to the corresponding locations.

Moving on to defining the sourcing and inventory policies.

Originally, if you plan your supply chain without suppliers, the factory could still be producing the products using the raw materials. The inventory policy in this case should be set to Unlimited inventory to allow the factory to have as many raw materials in stock as required. The sourcing would not require any updates, since the factory would always have the raw materials in stock. i.e., no external source would be necessary.

In our case we need to provide the mentioned changes, since we decided to have suppliers. Let us start with defining the source of the raw materials, which is done in the Sourcing table.

Update the sourcing policy

- Navigate to the Sourcing table by typing Sourcing in the search field.

- Select all cells in the Product column by ctrl clicking them.

- Press Spacebar, select the just created [Products]

group from the drop-down list, then click Save.

As you remember we have 4 products now, 2 of which are raw materials, so we have to define that the distribution centers and the customers are working with the end products only. - Now add a new record by clicking Add.

- Set Delivery Destination to Factory.

- Now specify the plastic supplier by double-clicking the cell of the Sources column, unchecking (All Sites), and checking Plastic supplier.

- Set Product to Plastic.

- Now repeat steps 4-7 to define the silicon supplier for the factory.

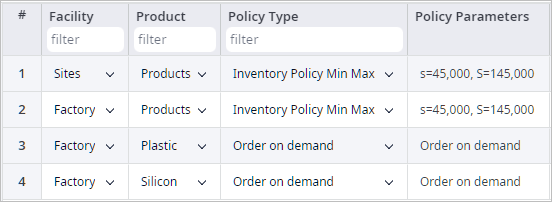

When done, the table must have the following data:

Now we will update the inventory policy of the factory. The new policy will consider the raw materials that are ordered on demand.

Update inventory policy

- Navigate to the Inventory table by typing Inventory in the search field.

- Select all cells in the Product column by ctrl clicking them.

- Press Spacebar, select the just created [Products] from the drop-down list, then click

Save.

This is done to define that the distribution centers deliver the end products only, and the factory has certain stock of end products. - Create a new record by clicking Add.

- Set Facility to Factory.

- Set Product to Plastic.

- Set Policy Type to Order on demand. The factory will order the required amount of plastic instantly on receiving a production order from any of the distribution centers.

- Set the Initial Stock, units to 50. We will assume that the factory initially has 50 m3 of plastic in stock.

- Repeat steps 4-8 to define inventory policy for the silicon product.

When done, the table should have the following records:

Update shipping policy

- Open to the Shipping table by typing Shipping in the search field.

- Create a new record by clicking Add.

- Set Source to (All suppliers).

- Set Destinations to (All sites).

- Define the default vehicle type in the Vehicle Type column.

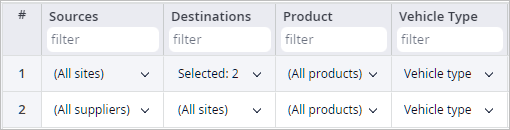

When done, the table should have the following records:

We have completed the second phase of this tutorial. We added raw materials, suppliers, and updated the sourcing and the inventory policies.

In the next step we will define bill of materials and update production policy. These steps will make the factory use the raw materials to produce the end products.

Click the link below to proceed to the next Phase 4.

-

How can we improve this article?

-