If required, orders can be split. By splitting an order you allow it to be delivered in several shipments, rather than in one. In this case the order is not considered completed until 100% of the requested amount has been delivered.

All split orders are easy to track in the custom Orders Table statistics.

Types of order splitting:

- Partial delivery — the shipping policies allow a received order to be split if required. In case of the LTL or LTL with periodic check policies you need to disable the Forbid partial delivery parameter to split orders based on the vehicle capacity. See the example for detailed explanation. In other words, if an order is too big to fit in a vehicle, it can be split into several parts to fit in the vehicles a site uses.

- Partial shipment — a customer or a site (distribution center or factory) placing an order may allow order splitting if required. The orders will be split based on the defined Minimum Split Ratio. See the example for detailed explanation. In other words, if you lack stock to deliver 100% of an order, you can split it by sending the stock you have now and delivering the rest later.

- Uniform Split (Multiple Sources) — the sourcing policy allows a received order to be equally split among the available sources (defined in the Sourcing table), which simultaneously supply the delivery destination. For example, if the demanded amount is 200 and there are 5 available sources, the customer will receive 40 items from each source.

- Split by Ratio (Multiple Sources) — the sourcing policy allows a received order to be split among the available sources according to the Ratio defined in the Parameters column of the Sourcing table.

Partial delivery is available if either LTL or LTL with periodic check is set in the Type column of the Shipping table.

A vehicle in this case is allowed to deliver part of the order that fits its capacity to later return, fetch and deliver the rest of it.

We will assume that:

- Source site has a fleet with 1 vehicle that has a capacity of 100m3.

- Priority is set to Big first.

- Partial delivery is allowed.

This is how it works:

- The policy chooses the biggest order from the queue (130m3), which exceeds the vehicle's capacity (100m3).

- Since partial delivery is enabled. the vehicle takes 100m3 and sets off to deliver this part of the order. The customer does not consider this order to be completed. The customer waits for the rest of it (30m3) to be delivered.

-

The vehicle returns to the source site.

The policy is triggered and it chooses the biggest order again from the general queue of orders from all customers.

The partially delivered order is treated by the policy by its initial volume (130m3),

so the new orders that have been added to the queue have to be 131m3 or more to be the biggest orders.

Unless they are, the vehicle will take the 30m3 the customer is expecting,

check if there are any other orders from that same customer it could fill the rest of its capacity with (70m3) and sets off to complete the order.

In case one of the new orders is 131m3 or more, the vehicle will fetch it first. Again, only part of it will be taken, so we will have two partially delivered orders that are waiting until their initial volumes will be the biggest among all other orders in queue.

Partial shipment can be allowed by a supply chain object that creates an order.

Partial shipment is available if Minimum Split Ratio is not set to the default value 1. By specifying the value greater than 0 and less than 1 you define the minimum ratio to split an order.

Allowing partial shipment:

- If you want customers to allow partial shipment, change the default value of the Minimum Split Ratio column in the Demand table.

- If you want a site (distribution center or factory) to allow partial shipment, change the default value of the Minimum Split Ratio column in the Inventory table.

We will assume that:

- A distribution center receives an order from a customer for 100 products.

- The available inventory is insufficient.

- The Minimum Split Ratio in the Demand table is set to 0.4. This means that our customer is ready to receive the placed order in several deliveries rather than in one. The order itself will not be considered fulfilled until all 100 products have been delivered. The order and its partial shipments can be tracked in the Orders Table custom statistics.

This is how it works:

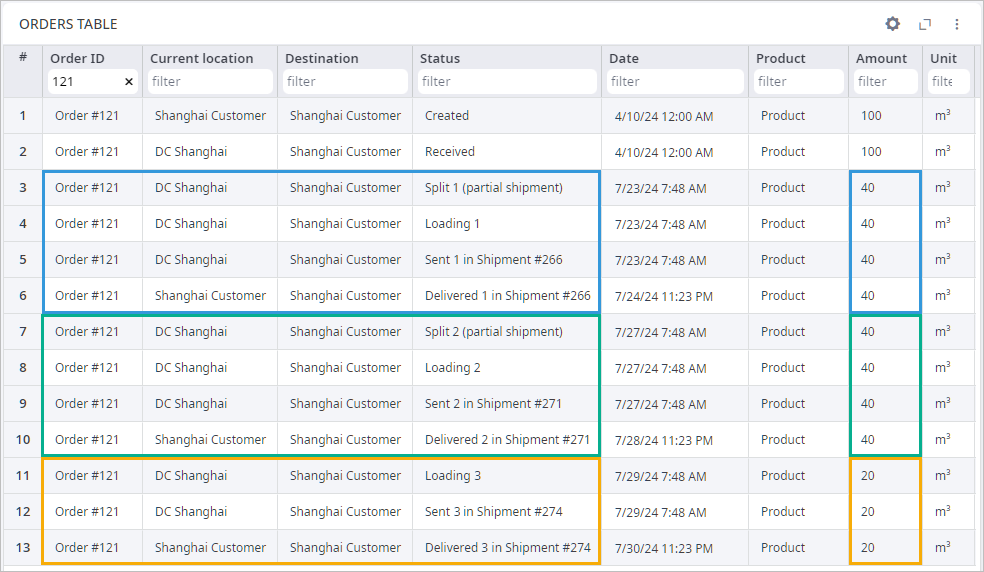

See the image below for reference of the example description.

- A distribution center receives an order for 100 products. The available inventory, however, is only 40 product items.

- The distribution center checks, if a customer is ready to receive only part of the order now and the rest of it later. The Minimum Split Ratio is set to 0.4, so this distribution center needs to have at least 40 product items in stock to send a vehicle to the customer with the first part of the order.

-

The order is split. The corresponding status Split (partial shipment) will show this in the

Orders Table.

The status name comprises:

- Split — the name of the action that took place.

- (partial shipment) — the type of split.

- A vehicle is loaded with 40 product items. This action is represented by the Loading started status in the Orders Table.

-

The vehicle is sent to the customer.

This action is represented by the Sent in Shipment #266 status in the Orders Table.

The ordinal number of the shipment does not have any reference to the split it is in. It is simply the number of the shipment in your supply chain.

- A vehicle is unloaded. This action is represented by the Unloading started status in the Orders Table.

- Finally, the shipment with the part of the order is delivered to the customer. This action is represented by the Delivered in Shipment #266 status in the Orders Table. The delivery of the current split is considered completed, but the order is not considered fulfilled, since we delivered only 40 product items out of 100.

- After the first split the inventory has no product items left in stock. At this point the distribution center will wait for the inventory replenishment orders to arrive. Once the received replenishment adds at least 40 product items, the distribution center will split the order again, send the second shipment with 40 (or more) items it has in stock. The status actions will reflect this with the same set of action names (Loading started, Sent in Shipment #271, Unloading started, Delivered in Shipment #271).

-

To complete the order, the distribution center must have the remaining 20 items in stock

(100 were ordered - 40 in the first Split - 40 in the second Split =

20).

Split is not available now, since partial shipment requires 40 items, while we need to deliver only 20.

If the inventory by that time has the remaining 20 items available, the distribution center will load them to a vehicle and send the products to the customer.

Once the remaining products are delivered to the customer, the order is considered completed.

The final shipment in this order is not considered a split of the order. It is the remaining part of the order, that is why statistics have only the Loading started, Sent in Shipment #274, Unloading started, Delivered in Shipment #274 statuses.

On the screenshot below you can see the illustration of the partial shipment example. The order was delivered to the customer in 3 shipments. The order was split 2 times (40 product items were delivered in each shipment), the third shipment delivered the remaining amount (20 product items).

-

How can we improve this article?

-