In this example we will analyze the MRP policy calculations with the defined aggregation period.

Having defined the order placement day, the policy considers the Aggregation period, days parameter to see if order aggregation is required. If the parameter's value is greater than zero the policy will aggregate all replenishment orders within the specified period of time.

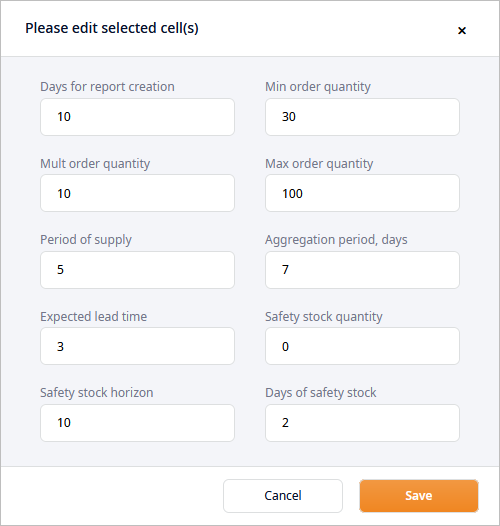

Policy parameters are described here.

In our example the aggregation period constitutes 7 days, which means that the policy will aggregate all replenishment orders that must be placed within the period of 7 days starting from today.

Today is the day on which the report is made. The first replenishment order is also placed on this day.

Orders aggregation

The numbered lists in tutorials are actually checklists. Click the numbers to save your progress!

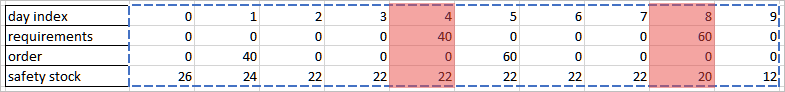

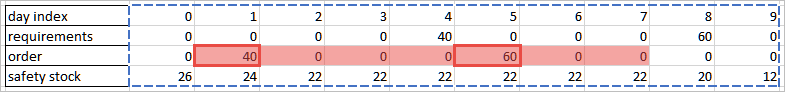

- The policy determines that safety stock violation is possible on days #4 and #8 within the report creation period (defined by the

Days for report creation parameter).

- Then it estimates replenishment amounts that must be received on these days.

In our case they must be 40 and 60 for days #4 and #8 respectively.

- With the next step the policy estimates the days on which the replenishment orders must be placed.

The Expected lead time parameter is set to 3,

so the first order will be planned on day #1, and the second order will be planned on day #5.

Here we can already tell that the replenishment order will not be placed, since no order is planned on day #0.

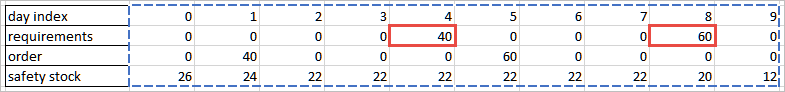

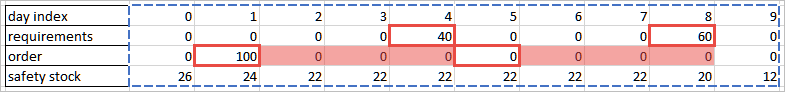

- Now the policy checks the Aggregation period, days parameter to see if aggregation is required.

The parameter is set to 7, which means that all orders within the period of 7 days must be combined into one big order.

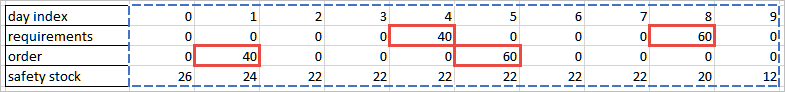

- The policy estimates the aggregated order for day #1 (40 + 60 = 100),

then sets the added order from day #5 to 0 to not consider it in calculations,

which will be done on the coming days.

- Finally, the policy moves on to the next order placement day (which is beyond the just processed aggregation period) to proceed from step 4 of this scenario.

-

How can we improve this article?

-